John Killmer brings more than 30 years of experience working in Agtech from serving as President of Monsanto China to now acting as CEO of St. Louis-based APSE.

We tapped him to talk to us about what APSE is working on with RNAi and why it’s going to make a huge difference in agriculture in the next five years.

RNAi—what is it and why is that important in Agtech right now?

RNAi is a very new technology. Really, it was only made fairly clear around 1998. Everyone has heard of DNA and proteins, DNA is the library of information and RNA is between DNA and proteins.

It’s the template that proteins are patterned from. And RNAi stands for interference—small pieces of RNA that can block the template and prevent the formation of a protein.

Via that process, it can do many things. It can change the characteristics of a plant, it can kill insects, it can control disease, it can reverse the tolerance that certain weeds have built up to herbicides, it can reverse the tolerance that certain insects have built up to certain insecticides so it’s a very versatile tool.

The high cost of supplying large quantities of RNA for RNAi applications is a hurdle in Agtech, how is APSE working around that?

That’s the primary focus for APSE. We look at the main impediments to topical RNA, something that’s sprayed on, it’s important to know that it is sprayed on, and it’s not a GMO application. So there are some advantages there.

However, RNA has never been made in large quantities, and if you’re going to use it as a spray in a field or as a seed treatment, you need to produce large quantities. Probably less than 10 years ago, one gram of RNA could easily cost $100,000.

Obviously you aren’t going to be spraying something that costs $100,000 a gram, even though the use rate is around 1-5 grams an acre. So there needed to be a process to produce RNA both at low cost and at high purity and APSE is developing technology to do that.

The magnitude that APSE is planning and the industry needs are not gram quantities but ton quantities. Our target is to produce the RNA at $2 a gram—a huge change in the cost structure, making topical RNA very viable from an economic standpoint.

Talk a little about that technology, what is different about what APSE is doing with RNA and RNAi?

There are basically four ways to make RNA.

A chemical approach that’s quite expensive and limited in the type of RNA you can make; in vitro transcription which is a test-tube process that you can scale up, but you can’t really scale it up to levels where you’d produce high volumes; a fermentation process that can be used to produce RNA, but it produces very messy RNA that’s quite expensive to clean up; and the APSE process.

APSE uses fermentation, but in our process we transform a microorganism to produce the RNA we want, but at the same time we produce a protein container. We can get the RNA trapped in that protein container. That protein container is easy to separate from all the other junk in the fermentation mixture.

What are some differences or advantages of working with RNA and RNAi versus GMOs?

There are things that you simply can’t do with a GMO. One example is if a weed becomes resistant to a herbicide, you’re not going to genetically modify the weed. So you can develop technology with RNAi that you can spray on and make that weed susceptible to the herbicide again.

The other thing is, there are many places in the world where the benefits of GMOs are simply not available to the producers, and we believe that eventually, RNAi technology will be able to bring the same benefits to the producer but in a non-GMO mechanism.

Even in places where GMOs are common, there may be certain traits, say drought tolerance, there may be traits that you don’t necessarily need in a crop all the time. It is possible with some appropriate discoveries, they aren’t here yet, that you would be able to modify a crop plant in the field when you realize that you’re going into a drought and you can do that on an as-needed basis.

It’s a term we call traits on demand. It’s not ready for prime time yet but definitely the technology is there.

Why do you think St. Louis is a good location for APSE and companies similar to it?

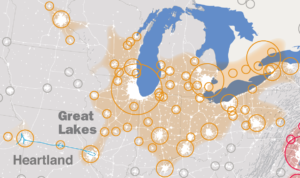

The St. Louis area has the highest concentration of PhD plant scientists, not just in the country but in the world.

And that’s primarily a result of Monsanto and the Danforth Plant Science Center. Both of those locations have made St. Louis an attractive location for various companies that are in agriculture and also various startup companies.

We find a number of the smaller companies based on plant science relocating to this area to be near those areas of expertise and the talent base that they require. Then of course those companies when they come in bring more PhD plant scientists and it’s a domino effect.

On top of that, a lot of these plant scientists in the area have new and innovative ideas want to branch out on their own and start their own companies so it’s just a perfect place for them.

What is the most challenging aspect of your work?

I’d say the two most challenging things are investment capital and establishing collaborations with players in the industry who have a vested interest in this technology. I’m very confident in our technology and the needs for our technology as the industry progresses forward, but of course, there are external factors.

The various people who will be needing this technology are at all different stages of implementation. We look for collaborations with them, we look for resources from investors.

And the most rewarding aspect?

The progress that you can see in the laboratory over fairly short periods of time is just phenomenal. In the year I’ve been at APSE, I’ve witnessed some remarkable discoveries that have really enhanced our ability to meet that $2 a gram goal. It’s really quite exciting to be a part of that.

What’s coming up next for APSE in the future?

We plan to have our technology ready for the market place within three years and that will be somewhat dependent on discoveries that we make in the meantime. So we plan to have production technology slightly in advance of when we, and many others with us, anticipate, the entry of topical RNAi into the market which will be around 2019 or 2020.